Ultimate Overview to the Best Welding Shirts for Extreme Working Conditions

Wiki Article

A Comprehensive Guide to Selecting the Right Welding Shirts for Optimum Efficiency and Protection in Hazardous Work Environments

Choosing the suitable welding t shirt is not just a matter of comfort; it is a critical decision that influences both efficiency and safety and security in harmful environments. Aspects such as fit, material make-up, and safety attributes play critical roles in guaranteeing that a welder stays unhurt while keeping optimum functionality. Comprehending these important components can significantly affect end results on the work. Yet, the nuances of this selection typically go ignored. What details features should one prioritize to ensure optimal protection and efficiency in the area?Value of Welding Shirts

Welding t shirts play a vital role in the security and performance of welders, with the right garment dramatically influencing both protection and convenience. In the welding career, employees are routinely revealed to extreme warm, triggers, and harmful materials, making proper clothing necessary to reduce dangers. A well-designed welding t-shirt can act as a barrier versus thermal burns and various other injuries, therefore securing the welder's skin from unsafe aspects.Furthermore, the fabric and fit of welding t shirts directly affect a welder's ability to execute tasks effectively. Loosened or improperly suitable shirts can snag on devices or obstruct movements, bring about prospective accidents. On the other hand, shirts that are as well tight may restrict movement, boosting exhaustion and minimizing general effectiveness.

In addition to security concerns, comfort continues to be critical. A welding tee shirt that enables for breathability while offering sufficient protection can improve focus and efficiency. As a result, selecting high-quality welding t-shirts is not just a matter of preference; it is an important element of a welder's toolkit, guaranteeing both safety and optimum performance in challenging working problems (Best Welding Shirts).

Key Attributes to Take Into Consideration

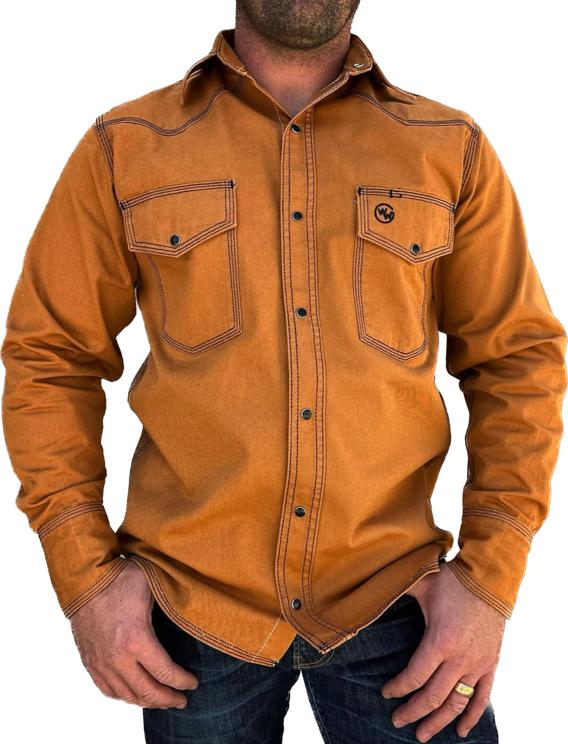

When choosing a welding t-shirt, a number of essential functions ought to be prioritized to guarantee both safety and security and comfort. Most importantly, proper fit is essential; a tee shirt that is as well loosened might snag on equipment, while one that is also limited can restrict movement. Search for shirts with enhanced seams and long lasting stitching to enhance longevity, specifically in high-stress locations.Next, consider the style elements, such as collar style and sleeve length. A high collar can give extra neck defense, while lengthy sleeves shield the arms from triggers and warm - Best Welding Shirts. Flexible cuffs can assist secure the sleeves, avoiding them from rolling up throughout work

Air flow is another essential element. T shirts with breathable textiles or mesh panels promote air movement, which can be helpful in warm atmospheres. Furthermore, the weight of the material issues; much heavier materials normally supply better protection but might prevent convenience.

Lastly, examine safety and security functions such as flame resistance and anti-static homes. These features are essential for minimizing fire risks and guaranteeing compliance with safety regulations. Focusing on these crucial features will lead to a welding tee shirt that improves performance while safeguarding the user.

Finest Materials for Defense

Cotton is extensively utilized due to its breathability and comfort; nevertheless, it needs to be treated to enhance its flame-resistant homes. Heavyweight cotton or combined products can provide an equilibrium between comfort and protection. Jeans, understood for its toughness, offers an additional layer of security while keeping flexibility for ease of motion.

Sizing and Fit Guidelines

Selecting the suitable dimension and suitable for welding t-shirts is as vital as the materials from which they are made. An ill-fitting tee shirt i loved this can hinder movement, increase exhaustion, and pose safety risks during welding procedures. To guarantee optimal efficiency, it is vital to refer to the manufacturer's sizing chart, which typically associates dimensions with particular dimensions.When examining fit, take into consideration both the body measurements and the planned use the shirt. A welding t shirt should allow for a full series of activity-- particularly in the arms and shoulders-- without being excessively loose, which could catch on equipment or subject skin to hazards. It is suggested to decide for t shirts that feature an unwinded fit, as they give convenience while maintaining safety requirements.

Furthermore, focus on the shirt's size; it must cover the torso appropriately to avoid stimulates or molten steel from getting in. Sleeves must be long sufficient to ensure protection while working, ideally ending at the wrist or just past. Lastly, think about the capacity for layering; if the t-shirt will certainly be used over other protective gear, ensure there suffices room for additional garments without endangering security.

Maintenance and Care Tips

Proper upkeep and care of welding tee shirts is important to prolonging their lifespan and making sure ongoing security and efficiency. To preserve the integrity of these specialized garments, it is necessary to follow specific treatment guidelines. Always examine the manufacturer's label for washing instructions, as various products may have differing requirements.When cleaning welding t-shirts, use a mild detergent and avoid making use of bleach or textile conditioners, as these can endanger the protective top qualities of the material. It is recommended to wash t-shirts individually from various other garments to stay clear of contamination from dust or fibers that may stir up. Furthermore, think about using chilly water to protect the textile's stamina.

After washing, Check This Out topple completely dry on low warm or air dry, as heats can damage the material and impact its protective properties. On a regular basis check the t shirts for signs of wear, such as fraying seams or holes, and replace them as needed to maintain security requirements.

Verdict

In final thought, choosing the proper welding t shirt considerably adds to safety and security and performance in dangerous job atmospheres. Eventually, an appropriate welding shirt serves as a crucial part in advertising both security and efficiency in welding operations.Report this wiki page